| Unit Price: | USD 1000.0000 / Piece/Pieces |

|---|---|

| Min. Order: | 10 Piece/Pieces |

Basic Info

Model No.: Zp-004

place of origin: China

standard: Ansi, Bs, Din, Gb, Iso, Jis, Jpi, Asme

Standard: Gb

Type: Welding Flange

Material: Tantalum

Structure: Flanges

Connection: Welding

Sealing Surface: Fm

Manufacturing Way: Forging

Certificate: Iso9001

Color: Silver White

Purity: 99.95%

Feature: Corrosion Resistance

Surface: Polishing

Product Name: Tantalum Flange Ansi Welding Neck Slip On Threaded

Kay Words: Thin Tantalum Bar

Additional Info

Packaging: Vacuum package/paper/wooden box

Productivity: 10000PCS/MONTH

Brand: ZHIPU

Transportation: Ocean,Air,Land,Express

Place of Origin: Baoji

Supply Ability: 10000PCS/MONTH

Certificate: ISO9001

HS Code: 8486909900

Port: Shanghai,Qingdao,Tianjin

Product Description

Baoji Zhipu non-ferrous metals processing co., ltd was established in 2003 and specialized in deep processing of refractory metals field. In 13 years` time, we have been focusing on tungsten, Molybdenum and tantalum finish machining parts in vacuum application industry, especially on vacuum furnace, atmosphere furnace and high temperature furnace. We have accumulated quite experience and technology in technology research and development, furnace transformation, vacuum furnace structure technical exchange and refractory metals'deep processing technological exploration and have been to main supplier of vacuum furnace material and heating room. Now, Zhipu Company is awarded to high-tech enterprise, Shaanxi well-known trademark enterprise and is authorized by the world third party company---- TUV Rhineland Germany. So far, our total assets have 93 million Yuan and 117 employees, among of them, 8 senior engineering and technical employees, 36 intermediate technical employees and more than 63% employees above college education degree.

In recent years, according to change and demand of new market, company have cooperated with domestic university and research institute and established technology research and development center, aiming at in research of photovoltaic equipment, ynthetic sapphire equipment and refractory metals` furnaceparts. Our products have various series branch: tungsten,

Stable Niobium Flang Pure Niobium Flange

and electrodes. Now, we have 20 patents and some of technologies and products are filled of domestic blank.

Products lists:

1. Tungsten, molybdenum and tantalum parts and heating room series products in all kinds of high temperature furnace;

2. Tungsten, Molybdenum Products in crystal furnace of PV industry;

3. Various single crystal furnaces thermal field tungsten and molybdenum products in sapphire industry;

4. Diaphragms and electrodes products in various instruments.

Tungsten ProductsTantalum Niobium Products Other Products

High Purity Niobium Flange

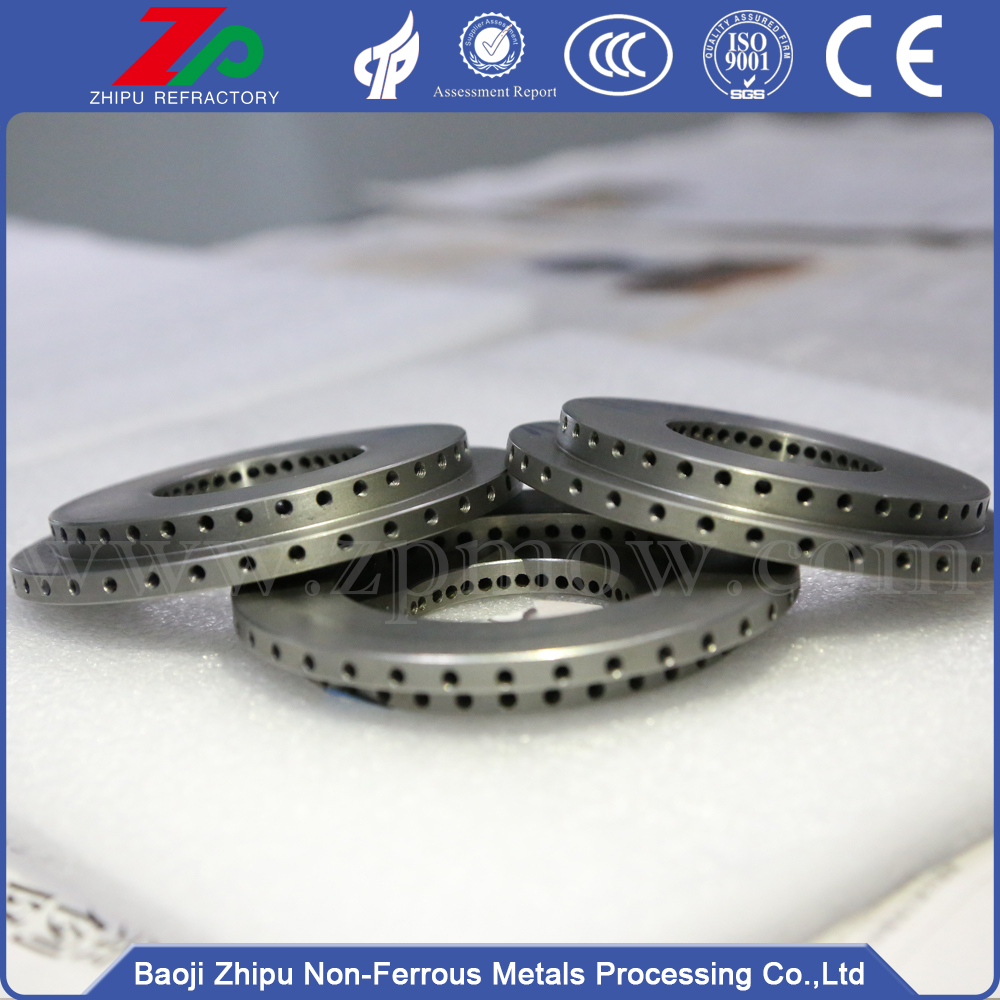

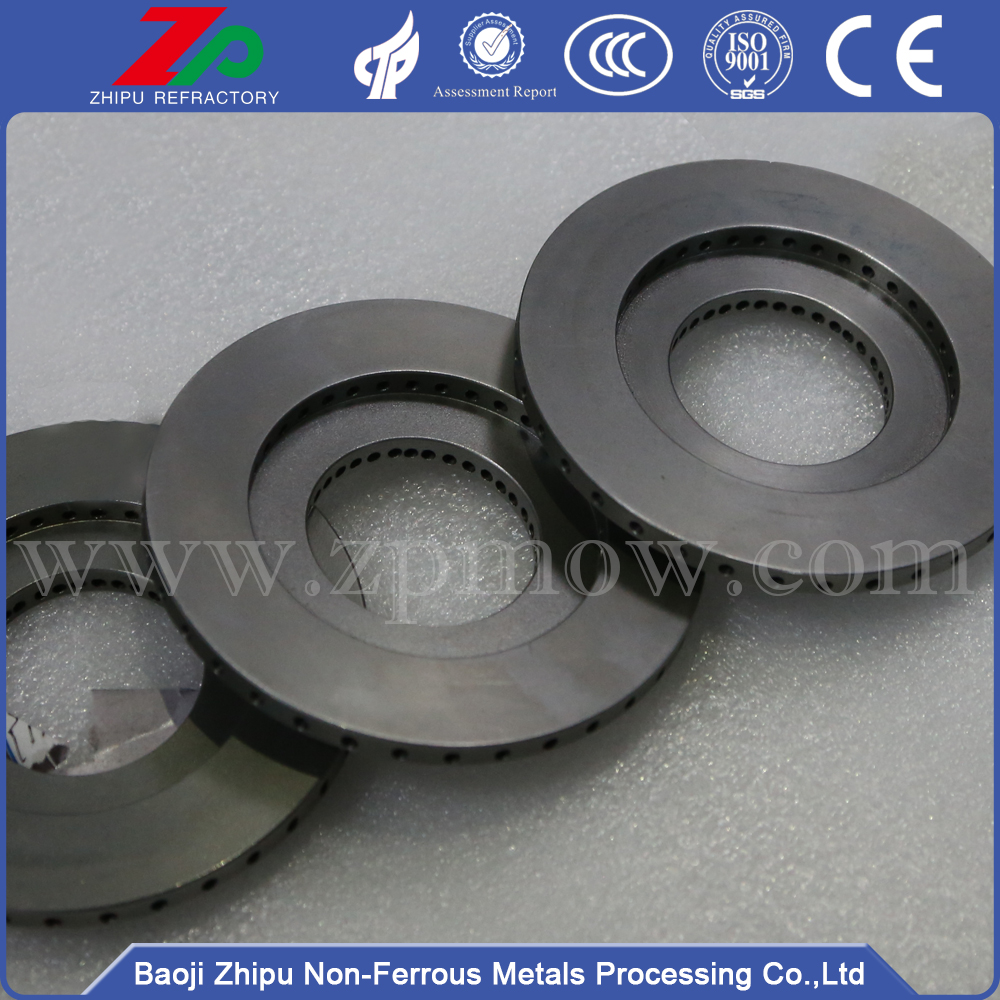

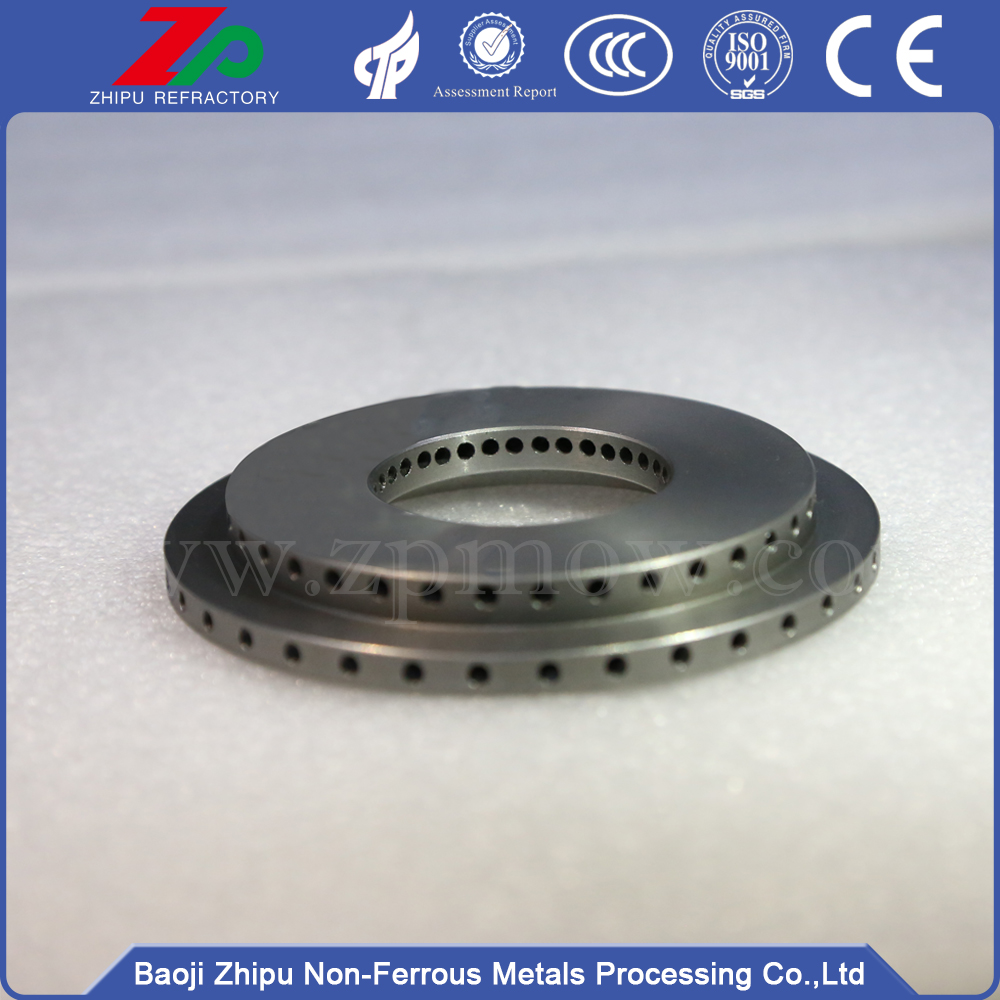

Tantalum Flange ANSI Welding Neck Slip on Threaded is the main products of our company. Tantalum Flange ANSI Welding Neck Slip on Threaded is widely used in industrial, eapecially used in single crystal furnace and vacuum furnace.

The material of Tantalum Flange ANSI Welding Neck Slip on Threaded belongs to refractory metals, and Tantalum Flange ANSI Welding Neck Slip on Threaded has the high melting point. so the feature of Tantalum Flange ANSI Welding Neck Slip on Threaded is high temperature resistance.

|

Product Name:Tantalum Flange ANSI Welding Neck Slip on Threaded Material:Tantalum Grade: Tan Purity: 99.95% Specifications: According to the customer's requirement Application: Industrial

|

|

Production Name |

Tantalum Flange ANSI Welding Neck Slip on Threaded |

|

Execution standard |

GB/T3877-83 |

|

Brand |

Tan |

|

Specification |

1:Diameter of Wire:Dia>0.015mm, Length<10000mm |

Technology: Forging rotary forging - car light - polishing - drawing - alkali washing, etc.

Classification of Tungsten rod surface:

(1) Black Tungsten Rod

(2) Polished Tungsten Rod

Classification of Tungsten bar material:

(1) Pure Tungsten bars: Tungsten content greater than 99.95%

(2) High temperature Tungsten (W La alloy): lanthanum 0.4~1.2, Tungsten content except for the residual impurities

TZM Tungsten rod: W-0.5Ti-0.07~0.12Zr-0.01~0.04C

Application:

(1) For making electric vacuum device and electric light source parts

(2) Suitable for machining parts of ion implantation

(3) As high temperature heating and high temperature structural parts

(4) In glass and refractory fiber industry as furnace electrode, working at 1300 DEG C glass solution, long service life

(5) Used as electrode in rare earth industry

Requirements of Molybdenum Rod:

Wrought Tungsten rod allows the oxide film and the slight skin hammer marks, polished molybdenum rod surface showed no significant oxidation of metallic luster.

Customers can be customized with a variety of specifications of products, welcome to inquire!

Technological process: Tungsten wire rope (raw materials) - inspection - hot - leveling and annealing - alkaline cleaning - inspection - provenzano - vacuum annealing - cold rolled - leveling - shear vacuum annealing - inspection - packing

Application: Used in vacuum devices, power semiconductor devices, heating element, heat insulation screen, molybdenum boat, etc; TZM molybdenum plate series, still can do prevent radiation shielding material, high temperature furnace structure materials, etc

© 2019 CHINA WAY. All Rights Reserved. Baoji Zhipu Non-Ferrous Metals Processing Co., Ltd., Inc. All rights reserved. site map. sitemap.html